What Does a Box Maker's Cert Stamp Mean to you?

Cert Stamps are More Important Than You Think

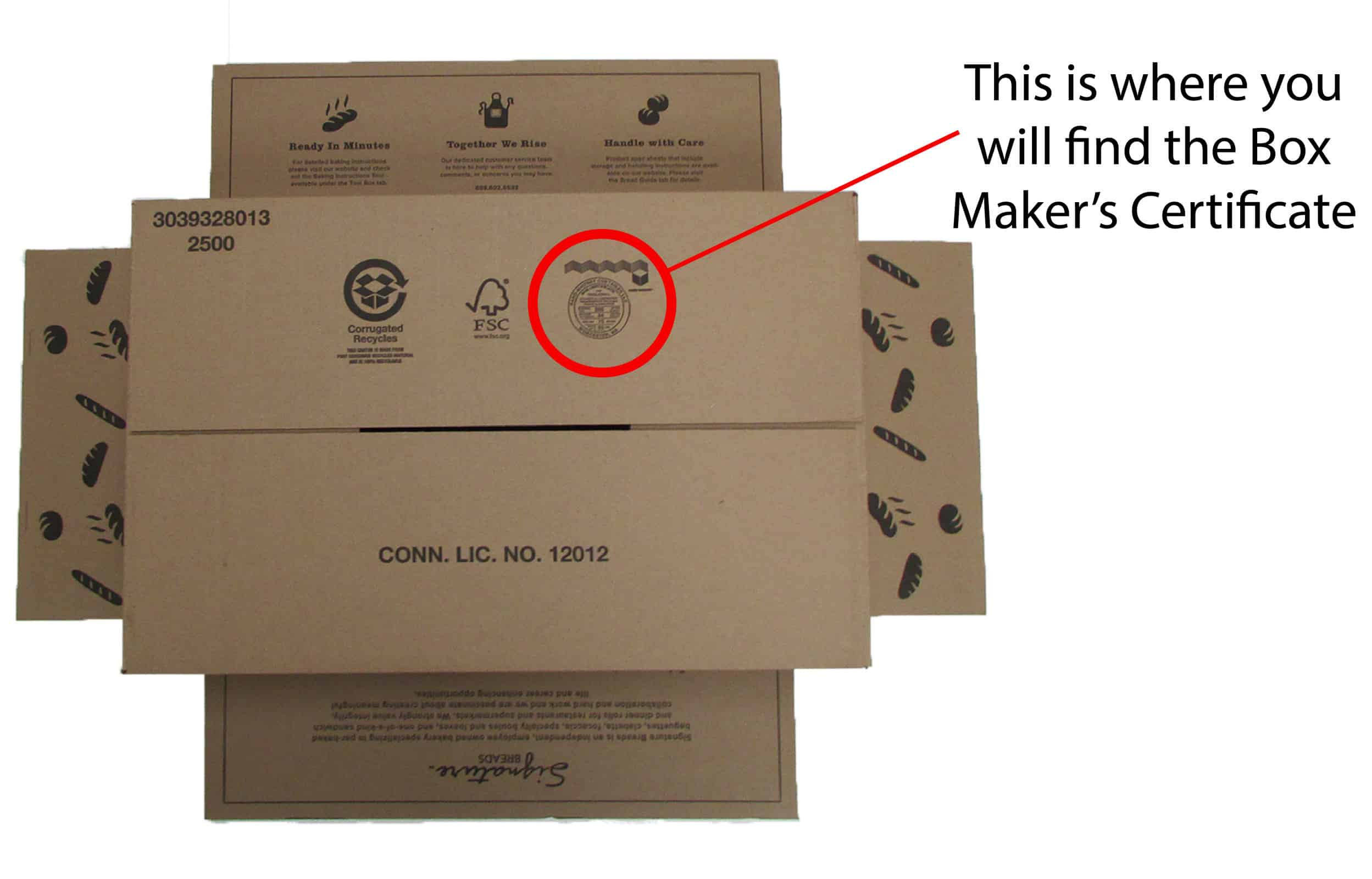

What goes unnoticed by most but is on almost every box you buy? A cert stamp! You may have noticed the circle on the bottom of most of the packages delivered to you. But chances are you’ve never really sat down and thought about why it’s there or what significance it has.

The cert stamp, or the Box Manufacturers Certificate, is important to both the box manufacturer and the product manufacturers. For the box manufacturer, it certifies that the box they made is the correct strength. For the company that purchases the box, it assures them that they can rely on the packaging to carry the amount of weight its intended for.

Where Did it Come From?

Although its not mandatory, The Box Maker’s Certificate has been in use for quite sometime. The trucking industry has used a certificate of their own dating back to the 1930’s. But not until 1968 did the rail and trucking industry begin using a common cert stamp. It has been mostly unchanged since then. The biggest alteration came in 1991. It was in this year that they began to allow not only the Mullen test but also the Edge Crush Test for box testing.

How Do I read a Cert Stamp?

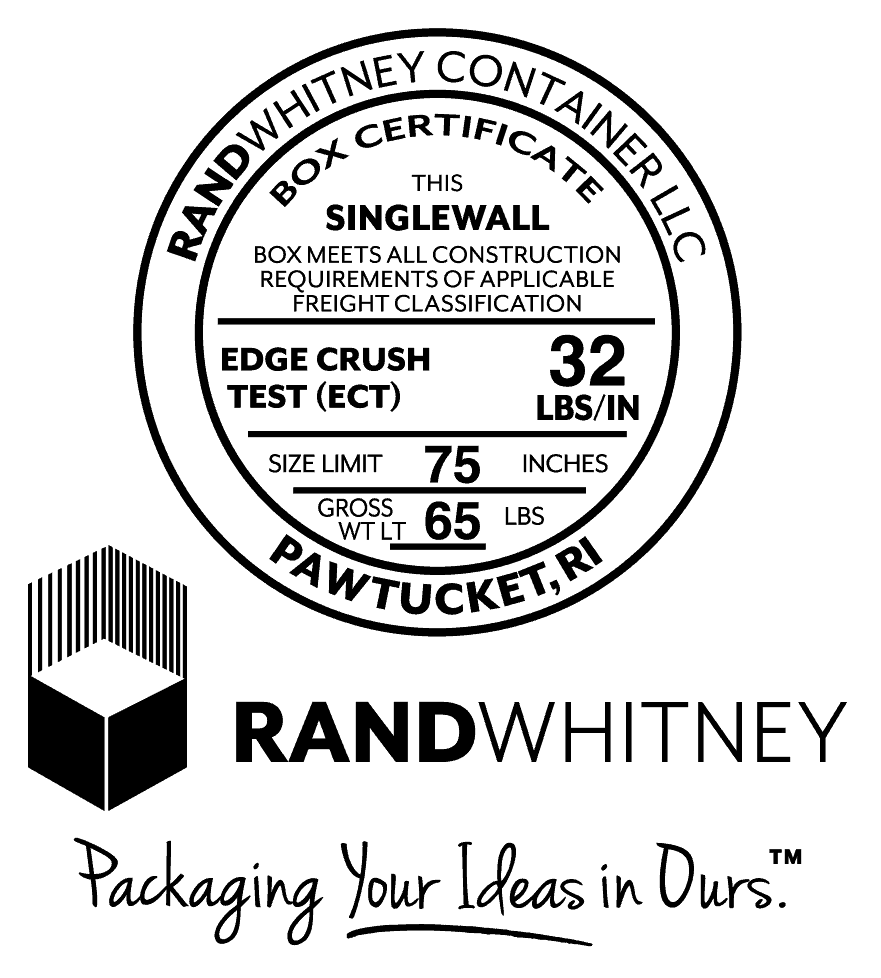

Knowing what a cert stamp means is one thing but knowing how to interpret the information is another.

Starting from the top, where the cert stamp reads “Rand-Whitney Container LLC“ is where you will find the name of, you guessed it, the manufacturer. This is who produces the boxes. It may seem redundant to have the name of the manufacturer on the box you just bought from them. However, a lot of larger companies buy boxes from multiple companies.

The next key piece of information is where “Single Wall” is in bold font. This tells you how the board is constructed. A single wall box will consist of 3 pieces of paper that have been corrugated together. This finished board will look like this:

Single Wall is the most common, but double and triple wall can be used to construct a stronger box. A double wall board will consist of 5 pieces of paper that have been corrugated together. Instead of one fluted section it will have two and will look like this:

The cert stamp will continue to say: “This Single Wall box meets all construction requirements of applicable freight classification”. This is the box makers promise that the box is properly constructed and meets its standards.

Mullen is the original test that was used in the corrugated industry. However, the most common way to test a box is using the Edge Crush Test. On the next row you will read “Edge Crush Test (ECT) 32 Lbs/In”. This is the strength the box is certified to. Obviously this will change depending on the strength of the box you order. Edge Crush test measures the stacking strength of a box. This is extremely relevant since the majority of your packages will ship stacked up, in order to fill a truck. The 32 Lbs/In is the weight per inch that can press down on the corrugated before it buckles.

If your boxes are Mullen tested, they will read something along the lines of “Bursting Test 200 Lbs per Sq in“. The Mullen test measures the boxes resistance to puncture, instead of its stacking strength.

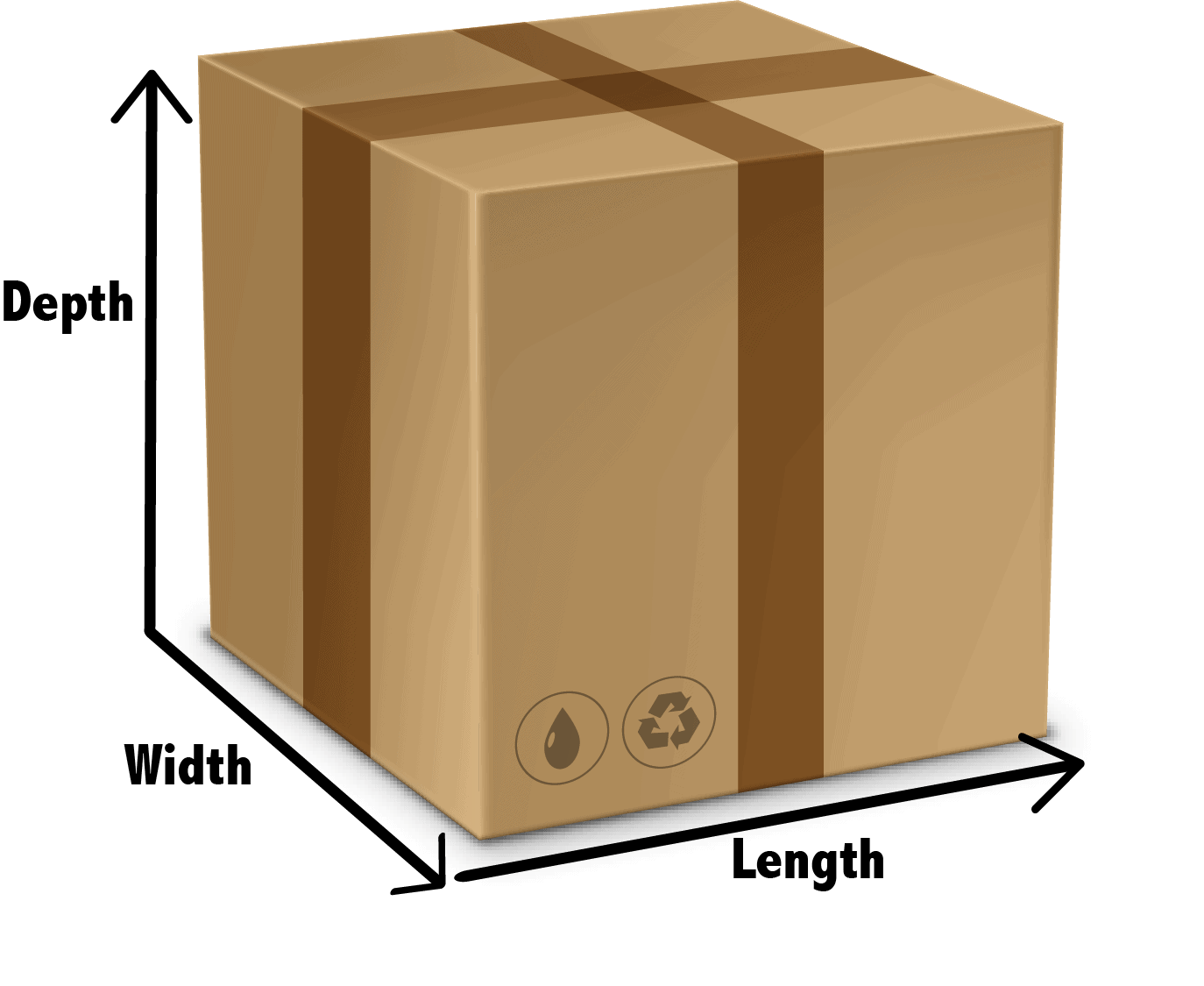

On the next line you will read “Size Limit 75 in”. What this means is that the outside dimensions, or OD, of the box cannot exceed 75 In. when added together. You’ll find the OD by adding Length + Width + Depth of the outside of the box. This is important to you because if the total outside dimensions exceed this number, the box as a whole will become weaker.

Going down one more row, you will read “Gross WT LT 65 Lbs.” This will tell you the maximum weight of the contents that you can place in the box. However, when your filling your box it’s important to recognize that this is the absolute upper limit of what should be put in the box. Different materials or types of products will carry that weight differently and can cause damage to the packaging.

Finally, you will find the city and state where your package was manufactured. This tells both the customer and the manufacturer what plant the box was produced at. This allows them to easily get to the bottom of any problems with the box.