Strength in Simplicity: The Benefits of Sesame Tape in Corrugated Packaging

In the world of packaging, strength and stability are non-negotiable, especially when dealing with large boxes and bulk bins. While board grade, paper combinations, and packaging design all contribute to packaging strength, there is another way to improve performance that is often overlooked – sesame tape.

What Is Sesame Tape?

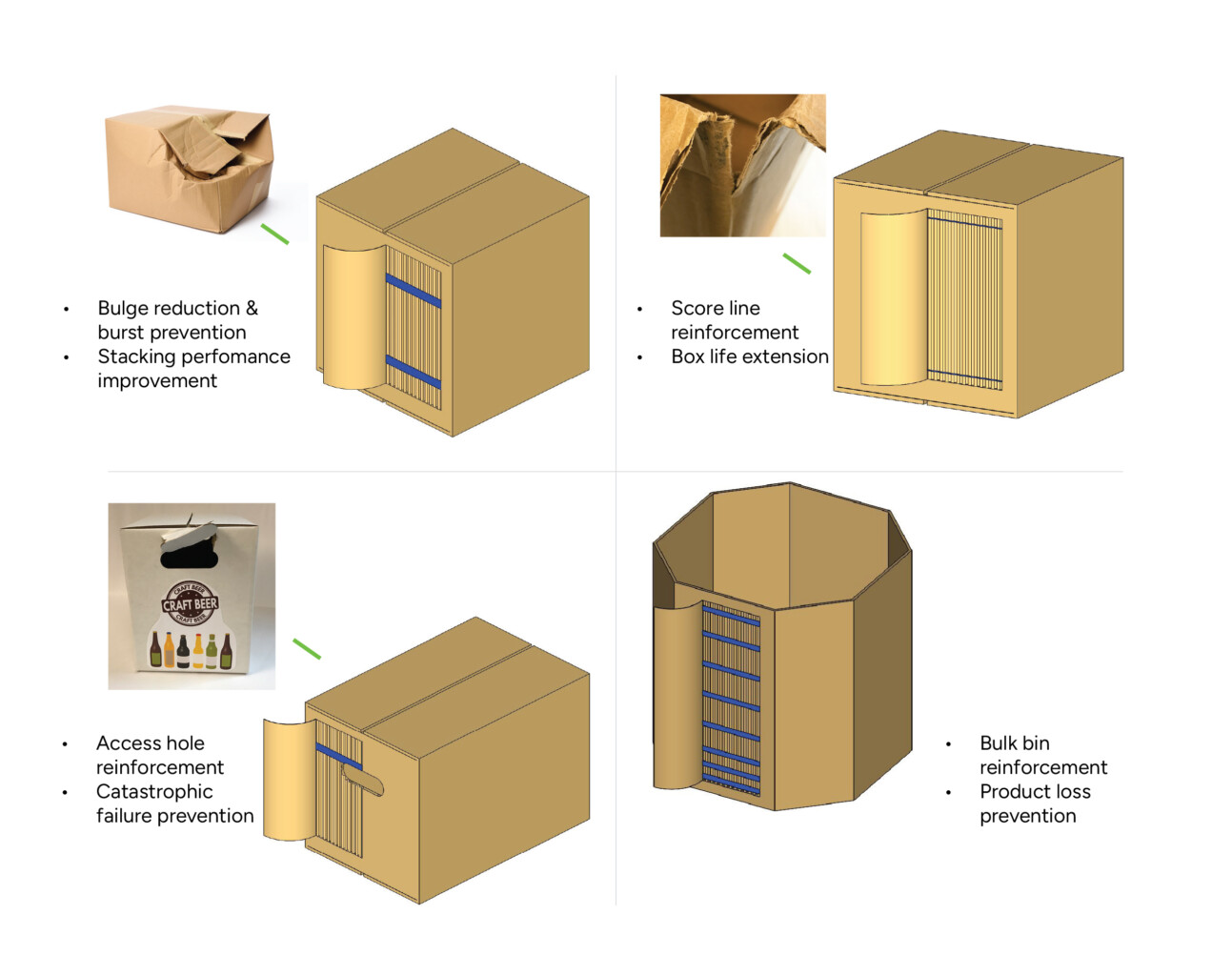

Sesame tape, also known as filament tape or reinforced tape, is an adhesive tape embedded with polyester filaments. These filaments run longitudinally through the tape, giving it exceptional tensile strength and resistance to tearing. In corrugated packaging, the tape often runs around the box to prevent bulging or along hand holes to prevent tearing.

Key Benefits of Sesame Tape in Corrugated Packaging

1. Enhanced Structural Integrity

Large boxes, when packed with heavy contents, are prone to flexing and bowing from internal pressure. The product inside presses on the walls which can cause bursting or tearing. Product in bulk bins, like the ones that hold watermelons in the grocery store, are only held up by the strength of the bin itself. Sesame tape acts as a reinforcement, distributing stress across the taped areas and preventing deformation.

2. Tear Resistance.

When packaging has score lines, hand holes, or handles, Sesame tape can greatly reduce the chance of tearing. This is frequently seen in product boxes like beer cases or produce trays that use hand holes for extra reinforcement. In this scenario, the tape runs parallel to the top of the hand hole within the corrugated. Produce trays see improved stacking longevity and up to 40 percent enhanced bulge resistance versus the same packaging with no reinforcement.

3. Cost-Effective Reinforcement

Compared to redesigning box structures or using thicker corrugated board, applying sesame tape is a low-cost solution that delivers high-impact results. It allows manufacturers to use lighter materials while still meeting strength requirements, reducing material costs.